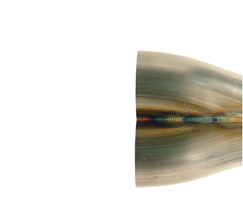

A collector with a 12 & 15 degree convergent angle offers the highest velocity and performance gains.

20 & 25 degree convergent angles are used where space constraints are the primary concern.

When ordering ask for a collector with a Tube O.D. the same as your primary tubes.

Collectors with 6 or 8 inlets are avialable by special order. A pair of 3 or 4 into one collectors are much more effective than a single 6 or 8 into one collector.

We have found ASTM A-269 304 micro seam welded tubing from Rath-Gibbsion to the highest quality and consistent available.

Some 304 & 321 stainless tubes sizes are also available in 20 gauge (.035")

For each component welded to the collector a Weld Fee will be charged. Fees vary with tube diameter, material type, and additional fabrication required.

Applications with a high and narrow operating range require less restriction at the throat of the collector.

Use the buttons on this page to learn about the options, terminology, and how we build our part numbers.